LASER ENGRAVE AND CUTTING DEVICES FOR FABRICATION AND DECORATION

INTRODUCING THE LV-290 AND LV-180 LASER ENGRAVERS

Boost your creativity and build your business with the Roland LV series laser engravers. Compact and really easy to use, the LV series cuts, engraves and marks on a huge range of materials to deliver impressive results at the touch of a button. Available in two sizes to fit your office or workshop and match your production needs.

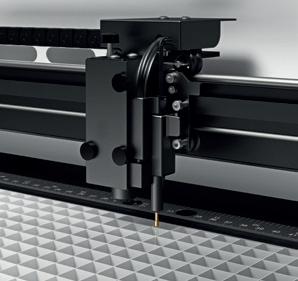

PRECISION CUTTING AND ENGRAVING

A non-contact CO2 laser engraves, cuts and marks complex shapes and text with crisp edges at high speed, without creating cutting debris. Unlike conventional computerised engravers, with the LV series cut surfaces have a smooth, clean finish without burrs, eliminating the need for final touch-up work. With no

engraving cutters to break or wear out, the laser always maintains a beautiful finish with no degradation in quality. The LV-290 is equipped with a CCD camera that supports positioning the material to accurately contour cut UV-printed graphics.

|

| IMPRESSIVE MEDIA COMPATIBILITY The LV series is compatible with an extensive range of materials, from plastics to wood, leather, paper, cork and much more. |

| SIMPLE, EVEN FOR BEGINNERS 1. The LV series is equipped with a range of functions which make it incredibly easy to accurately set up jobs, including a laser pointer to set the XY zero point and automatic height setting. 2. A simple and intuitive control panel navigates smoothly and quickly to the function you want to use. 3. The LV series comes standard with a Windows driver that can output directly from graphics software such as Adobe® Illustrator® and CorelDRAW®. You can set and save the optimal output parameters according to the materials and type of data. |

DESIGNED WITH SAFETY FIRST The LV series is Class 1-compliant under the “IEC60825-1” international standard for laser devices. The enclosed design prevents laser light from bleeding outside. If the cover is opened during processing, the safety interlock mechanism automatically halts laser activation. LED lighting illuminates the work area, allowing you to visually check whether processing is being performed safely and properly. | |